Pre-Shipment Inspection

Pre-shipment inspection, or PSI, is a part of the supply chain management function and an integral aspect of quality control procedures for ascertaining the value of goods purchased from overseas suppliers.

A pre-shipment inspection provides assurance that your products meet your quality standards before they are shipped.

A professional pre-shipment inspection gives customers the assurance that their products are ready to be sent to their destination market.

A pre-shipment inspection is a step taken by trade operators (buyers, suppliers, agencies) to inspect newly manufactured products before they are shipped for export/import.

This practice was introduced in 1994 in an effort to enhance international trade standards under the General Agreement on Tariff and Trade. This was later replaced by the World Trade Organization.

The aim of pre-shipment inspection is to ensure that the production of goods is in compliance with the principal specifications, contract, and/or purchase order. This is accomplished through an inspection wherein random samples of finished products are examined, typically when at least 80 percent of the order has been manufactured and packed for export.

The purposes of a Pre-Shipment Inspection are to:

- Examining the quality and quantity of products.

- Scrutinizing products for defects.

- Ensuring that products adhere to the safety requirements of the destination market.

- Issuing necessary reports for importing and billing.

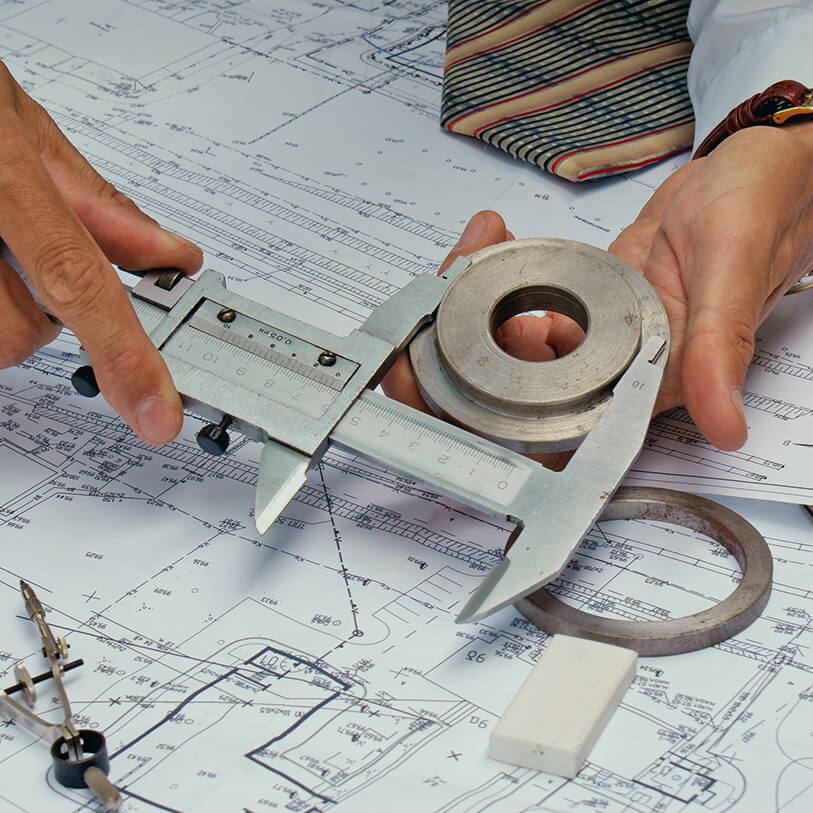

- Certified shipment authorities or trained personnels perform pre-shipment inspections. The procedure presents manufacturers with the opportunity to rectify their products before they are shipped, thereby averting costly import risks. The inspection addresses areas such as functionality, performance, sturdiness, appearance, and dimensions of the products.

Let's know a little more about what the pre-shipment inspection procedure entails.

1. On-Site Inspection

2. Authentication of Quantity

3. Selection of Product Samples

4. Verification of Workmanship

5. Check for Adherence to Governing Specifications

6. Testing

Product testing is a crucial component of PSI.

a. Function Testing

b. Mechanical Safety Testing

c. Electrical Safety Testing

7. Country-Specific Labeling And Marking

8. Preparing the Report